There’s often a great deal of confusion in the market about the different types of galvanized steel coatings and which option is best-suited to a particular project.

David Harrison, Market and Specifications Engineer at the Galvanizers Association of Australia, says this has been a longstanding issue – one that needs urgent attention because of the implications of using an unsuitable type of galvanized steel. Steel Pipe

“When there’s an issue with coating thickness, it’s usually because the specification was incorrect or misunderstood. Sometimes engineers and designers will order the right product but the person responsible for placing the order hasn’t picked up on all the details or they’ve just provided whichever product they had available,” says Harrison.

“It’s really important to specify according to a Standard, but also to understand how coating thickness is directly related to durability.”

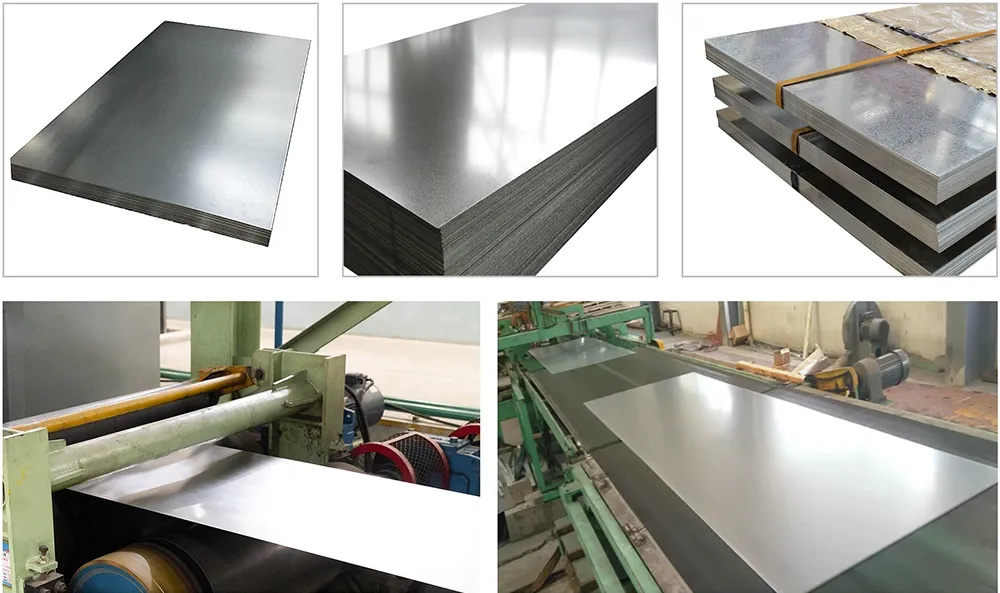

There are three main types of galvanized coatings that engineers should be familiar with:

Batch galvanized coatings provide a zinc coating that is thick, tough and gives complete coverage of the steel article. This combination cannot be achieved with other types of zinc coated steel.

Like continuous galvanized strips, the continuous galvanized tube coating is always thinner than batch galvanized coatings. Continuously galvanized tubes are widely used in light structural applications and, with appropriate repair to the cut-ends, can be ideal in many applications when the environment has relatively low corrosive effects, typically low to medium environments.

Regardless of its exposure, the durability of a galvanized coating is always in proportion to its coating thickness. The chart below shows the coating thickness and durability of the typical galvanized coatings used in construction, with the range of commonly available coatings indicated.

With batch galvanized coatings being the thickest coating and the only galvanized coating that provides complete coverage of the steel, it is the recommended option for engineers in most situations.

“Batch galvanized coatings are always thicker than continuous galvanized coatings, so for durable corrosion protection engineers should always specify that structural steel is galvanized to Australian Standards/New Zealand Standards 4680 ,” says Harrison.

Batch galvanizing also ensures that all surfaces, including cut-ends and welds, are fully galvanized.

He adds that, for residential housing, designers should be aware of the requirements for corrosion protection for structural steel in the 2022 NCC, which is given in Section 6.3.9 of the Housing Provisions Standard.

“It provides a minimum galvanized thickness requirement to location. Continuous galvanized hollow sections are only deemed to comply in areas of low corrosivity.”

Find out more about the performance of galvanized steel coatings in various environments.

create tells the stories behind the latest trends, innovations and people shaping the engineering profession. Through our magazine, website, enewsletters and social media, we spread the word about all the ways engineers help create the world around us.

Your email address will not be published. Required fields are marked *

WANT CREATE NEWS DELIVERED DIRECT TO YOUR INBOX? SUBSCRIBE TO OUR NEWSLETTER.

galvanized Square tube By subscribing to create you are also subscribing to Engineers Australia content. Please find our Terms and conditions here