From reinforcing water piping systems to serving as a critical component in the lithium-ion batteries that power electric vehicles, carbon black seems to be the secret behind nearly every aspect of modern civilisation

What do water pipes, tires, wires, cables, and lithium-ion batteries have in common? Besides being indispensable parts of everyday life, these items share a common ingredient: carbon black. HDPE Liner Price

Carbon black is a fine black powder generated through the controlled high-temperature pyrolysis of oil resides or natural gas. Aditya Birla Group’s Birla Carbon stands at the forefront of carbon black solutions worldwide, offering a comprehensive suite of products to meet the distinct needs of various niche industrial segments such as plastics, rubber, tires, coatings, inks, and batteries.

Yet, in addition to enhancing the durability, safety profile, and performance of end-products, the significance of carbon black extends far beyond. Let’s see how.

The rapid growth in population has led to an increased demand for water across various fronts. However, what many fail to realise is the role played by Birla Carbon’s Raven P-type carbon blacks in offering a viable solution to the issue of water accessibility. When incorporated into high-density polyethylene (HDPE) plastic pipes, these carbon black additives confer unmatched durability and performance advantages, surpassing those of conventional metal or concrete piping systems.

While HDPE pipes have a lifespan of up to 100 years when buried, several factors can accelerate molecular degradation, resulting in a significantly reduced service life. An often-overlooked phase is pre-installation, during which the pipes must be transported and stored while exposed to sunlight. Over time, UV rays from the sun break down the molecular chains within the HDPE, significantly weakening the structural integrity of the pipe. Raven P-type carbon blacks efficiently absorb UV radiation, thus preventing the plastic resin from degrading.

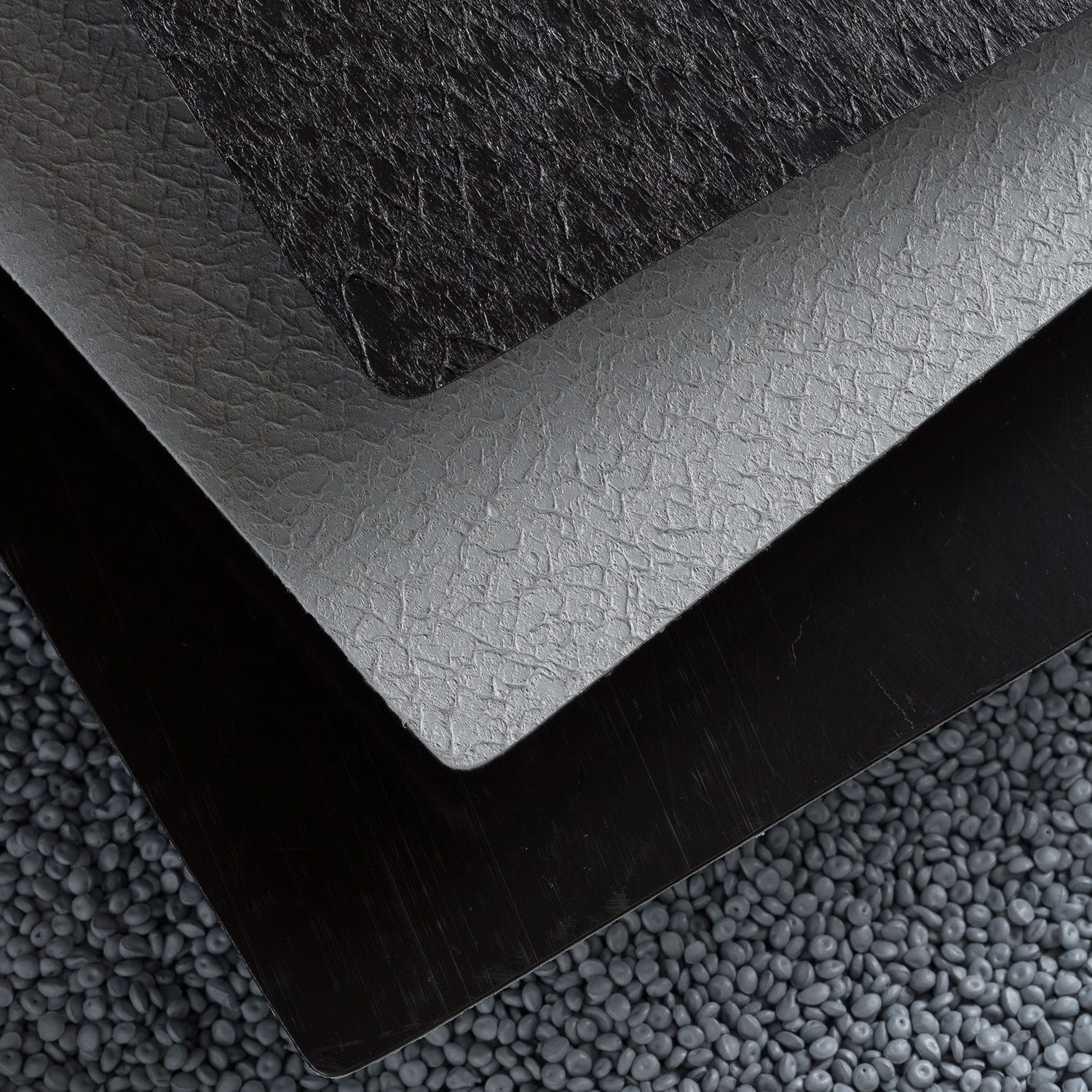

The efficacy of UV absorption hinges on several factors, one of which is the particle size of carbon black. Finer particles can cover a much larger surface area, enhancing their ability to absorb UV radiation. Raven P-type carbon blacks boast an average primary particle size of less than 25 nanometres, providing not only superior UV protection, but also an impeccably smooth surface finish.

Besides HDPE pipes, carbon black provides UV protection to a myriad of other plastic and rubber goods, ranging from anti-vibration systems, belts, and hoses, to sealing systems. It also serves as an efficient coating for automotive, architectural, and industrial components.

Even though it may seem counter-intuitive – given that the manufacturing process of carbon black itself is energy-intensive – its use helps pave the way for greener transportation. When tire tread compounds are reinforced with carbon black, it helps strike an optimal balance between wear resistance, rolling resistance, and traction. Birla Carbon has also developed specific carbon black formulations to reduce hysteresis in non-tread compounds and improve inner liner permeability, enhancing both tire lifespan and fuel efficiency. In fact, tires without carbon black would be hard-pressed to run over 100 miles!

But that's not all. Carbon black is also the most widely used conductive additives in lithium-ion batteries due to its ability to create robust electrical networks in the electrodes that can deliver superior performance even at high charge rates. Although conductive additives make up less than five percent of a typical lithium-ion battery, they are absolutely critical for maximising the energy density and rate capability of the active materials. Birla Carbon has engineered carbon black solutions such as Conductex i14 and CNT/CB Hybrid, both of which are aimed at increasing the driving range of electric vehicles and optimising overall battery performance.

Birla Carbon's portfolio of Raven and Conductex carbon blacks features a full-spectrum of colours, tonal shades, and UV protection properties, ranging from low tints to the jettest of blacks.

Carbon black also boasts exceptional electrical conductivity, making it well-suited for use in conductors and insulation shields of medium-and high-voltage cables. It imparts antistatic and electro-dissipative properties to insulative rubber and plastic materials, enhancing the safety profile of these applications while also extending their lifespan.

As a leading manufacturer and supplier of carbon black solutions, Birla Carbon plays an unseen yet pivotal role in making industrial components stronger, safer, and more sustainable. With its cutting-edge array of solutions tailored to a range of markets, the company is firmly committed to shaping the future of industrial innovation.

Geomembrane Mr. Sandeep Gurumurthi Group Head, Communication & Brand Aditya Birla Management Corporation Private Limited